Language: |

True

Unit:

Cái

-

|

|

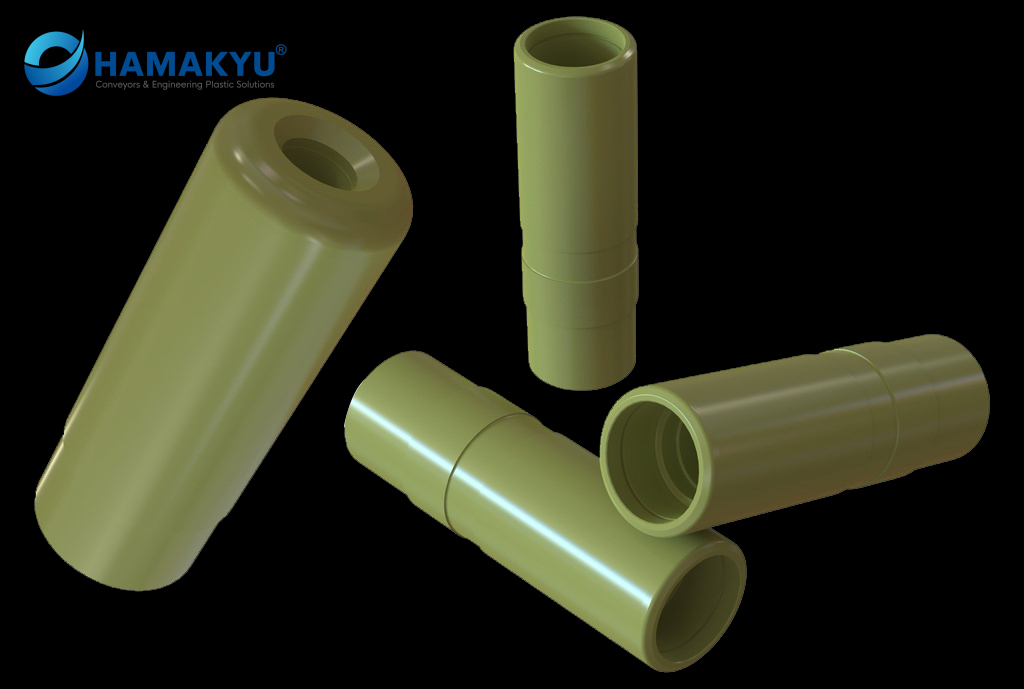

TIVAR Ceram P Ultra High Molecular Weight Polyethylene (UHMW-PE) is a self-lubricating, glass-filled material known for its bright green color. This grade is recognized for its excellent corrosion resistance, toughness, high impact strength, minimal moisture absorption, tensile strength, and exceptional wear resistance, which is better than virgin UHMW grades and other common polymers. In many applications, this leads to increased part life and reduced maintenance downtime.

TIVAR Ceram P UHMW-PE is commonly used in conveying, agriculture, lumber processing, material handling, pulp, paper, and steel milling industries due to its superior performance in high load, high speed, and severe sliding applications as a bearing and wear material for wear strip, linear bearings, wear liners and other bearing and wear applications.

It is available in various sheets, rods, and CNC machined parts, making it an ideal choice for applications requiring longer wear life than unfilled UHMW or other wear-resistant plastics. The increased part life and reduced downtime result in improved productivity and cost savings.

When comparing wear data from the ASTM G65 Sand Slurry Abrasion test (see below), TIVAR Ceram P demonstrates the lowest material loss, which is 15% lower than Unfilled Virgin UHMW and other wear-resistant polymers and metals. In wear applications involving particulate or abrasive media such as sand, Ceram P offers extended life for chain guides, wear strips, and other sliding wear parts, consistently delivering longer wear life in service and reducing maintenance costs by minimizing downtime

High load, High-speed, abrasive applications

Reduces noise

Self-lubricating

Wear-resistant

Corrosion-resistant

No moisture absorption

Alternative Products:

To install this Web App in your iPhone/iPad press ![]() and then Add to Home Screen.

and then Add to Home Screen.

![[132010392] TIVAR® BlueLine Plate, Size: 12x1220x3050mm, Origin: MCAM/Germany (Standard Size, 12x1220x3050mm)](/web/image/product.product/14828/image_1920/%5B132010392%5D%20TIVAR%C2%AE%20BlueLine%20Plate%2C%20Size:%2012x1220x3050mm%2C%20Origin:%20MCAM-Germany%20%28Standard%20Size%2C%2012x1220x3050mm%29?unique=0b50454)

![[132010435] Tấm nhựa màu đen TIVAR® BurnGuard UHMW-PE kích thước 12.7x1220x3050mm, xuất xứ: MCAM/Đức (To Order Size, 12.7x1220x3050mm)](/web/image/product.product/12976/image_1920/%5B132010435%5D%20T%E1%BA%A5m%20nh%E1%BB%B1a%20m%C3%A0u%20%C4%91en%20TIVAR%C2%AE%20BurnGuard%20UHMW-PE%20k%C3%ADch%20th%C6%B0%E1%BB%9Bc%2012.7x1220x3050mm%2C%20xu%E1%BA%A5t%20x%E1%BB%A9:%20MCAM-%C4%90%E1%BB%A9c%20%28To%20Order%20Size%2C%2012.7x1220x3050mm%29?unique=4fc75ef)

![[132013636] Tấm nhựa màu xanh nõn chuối TIVAR® Ceram P UHMW-PE kích thước 5x1000x2000mm, xuất xứ: MCAM/Bỉ (Sheet, To Order Size, 5x1000x2000mm)](/web/image/product.product/7574/image_1920/%5B132013636%5D%20T%E1%BA%A5m%20nh%E1%BB%B1a%20m%C3%A0u%20xanh%20n%C3%B5n%20chu%E1%BB%91i%20TIVAR%C2%AE%20Ceram%20P%20UHMW-PE%20k%C3%ADch%20th%C6%B0%E1%BB%9Bc%205x1000x2000mm%2C%20xu%E1%BA%A5t%20x%E1%BB%A9:%20MCAM-B%E1%BB%89%20%28Sheet%2C%20To%20Order%20Size%2C%205x1000x2000mm%29?unique=5a4801b)

![[132014371] TIVAR® Cestidur UHMW-PE Grey Sheet Food Grade, Size:2x1000x2000mm, Origin: MCAM/Germany (Sheet, To Order Size, 2x1000x2000mm)](/web/image/product.product/13334/image_1920/%5B132014371%5D%20TIVAR%C2%AE%20Cestidur%20UHMW-PE%20Grey%20Sheet%20Food%20Grade%2C%20Size:2x1000x2000mm%2C%20Origin:%20MCAM-Germany%20%28Sheet%2C%20To%20Order%20Size%2C%202x1000x2000mm%29?unique=e7ef260)

![[132014981] TIVAR® CleanStat™ EC FG UHMW-PE Black Plate, Size: 10x1010x2020mm, Origin: MCAM/Germany (Standard Size, 10x1010x2020mm)](/web/image/product.product/15123/image_1920/%5B132014981%5D%20TIVAR%C2%AE%20CleanStat%E2%84%A2%20EC%20FG%20UHMW-PE%20Black%20Plate%2C%20Size:%2010x1010x2020mm%2C%20Origin:%20MCAM-Germany%20%28Standard%20Size%2C%2010x1010x2020mm%29?unique=77da2dc)

![[132014959] TIVAR® CleanStat™ UHMW-PE White Plate, Size: 10x1220x3050mm, Origin: MCAM/Germany (Standard Size, 10x1220x3050mm)](/web/image/product.product/15101/image_1920/%5B132014959%5D%20TIVAR%C2%AE%20CleanStat%E2%84%A2%20UHMW-PE%20White%20Plate%2C%20Size:%2010x1220x3050mm%2C%20Origin:%20MCAM-Germany%20%28Standard%20Size%2C%2010x1220x3050mm%29?unique=6148708)

![[132014925] TIVAR® DS UHMW-PE Grey Sheet, Size: 3x1000x2000mm, Origin: MCAM/Germany (Sheet, To Order Size, Grey, 3x1000x2000mm)](/web/image/product.product/15067/image_1920/%5B132014925%5D%20TIVAR%C2%AE%20DS%20UHMW-PE%20Grey%20Sheet%2C%20Size:%203x1000x2000mm%2C%20Origin:%20MCAM-Germany%20%28Sheet%2C%20To%20Order%20Size%2C%20Grey%2C%203x1000x2000mm%29?unique=113427c)

![[132014223] TIVAR® DrySlide UHMW-PE Black Plate, Size:15x1010x2020mm, Origin: MCAM/Belgium (To Order Size, 15x1010x2020mm)](/web/image/product.product/12977/image_1920/%5B132014223%5D%20TIVAR%C2%AE%20DrySlide%20UHMW-PE%20Black%20Plate%2C%20Size:15x1010x2020mm%2C%20Origin:%20MCAM-Belgium%20%28To%20Order%20Size%2C%2015x1010x2020mm%29?unique=54862dd)

![[132013372] Tấm nhựa màu xanh green TIVAR® ECO UHMW-PE kích thước 35x1220x3050mm, xuất xứ: MCAM/Bỉ (Standard Size, 35x1220x3050mm)](/web/image/product.product/7868/image_1920/%5B132013372%5D%20T%E1%BA%A5m%20nh%E1%BB%B1a%20m%C3%A0u%20xanh%20green%20TIVAR%C2%AE%20ECO%20UHMW-PE%20k%C3%ADch%20th%C6%B0%E1%BB%9Bc%2035x1220x3050mm%2C%20xu%E1%BA%A5t%20x%E1%BB%A9:%20MCAM-B%E1%BB%89%20%28Standard%20Size%2C%2035x1220x3050mm%29?unique=d1dd9e0)

![[132014775] TIVAR® ECO antistatic UHMW-PE Black Sheet, Size:2x1000x2000mm, Origin: MCAM/Germany (To Order Size, Black, 2x1000x2000mm)](/web/image/product.product/14871/image_1920/%5B132014775%5D%20TIVAR%C2%AE%20ECO%20antistatic%20UHMW-PE%20Black%20Sheet%2C%20Size:2x1000x2000mm%2C%20Origin:%20MCAM-Germany%20%28To%20Order%20Size%2C%20Black%2C%202x1000x2000mm%29?unique=6d8f509)

![[132014850] TIVAR® ECO confetti fine black UHMW-PE Black Plate, Size; 40x1220x3050mm, Origin: MCAM/Germany (Standard Size)](/web/image/product.product/14946/image_1920/%5B132014850%5D%20TIVAR%C2%AE%20ECO%20confetti%20fine%20black%20UHMW-PE%20Black%20Plate%2C%20Size%3B%2040x1220x3050mm%2C%20Origin:%20MCAM-Germany%20%28Standard%20Size%29?unique=5fcd154)

![[132010520] TIVAR® H.O.T. UHMW-PE White Plate, Size: 20x1220x3050mm, Origin: MCAM/Germany (Standard Size, 20x1220x3050mm)](/web/image/product.product/14869/image_1920/%5B132010520%5D%20TIVAR%C2%AE%20H.O.T.%20UHMW-PE%20White%20Plate%2C%20Size:%2020x1220x3050mm%2C%20Origin:%20MCAM-Germany%20%28Standard%20Size%2C%2020x1220x3050mm%29?unique=16e16a9)

![[132014915] TIVAR® HPV UHMW-PE Blue Plate Food Grade, Size:30x1010x2020mm, Origin: MCAM/Germany (Sheet, To Order Size, 30x1010x2020mm)](/web/image/product.product/15005/image_1920/%5B132014915%5D%20TIVAR%C2%AE%20HPV%20UHMW-PE%20Blue%20Plate%20Food%20Grade%2C%20Size:30x1010x2020mm%2C%20Origin:%20MCAM-Germany%20%28Sheet%2C%20To%20Order%20Size%2C%2030x1010x2020mm%29?unique=e1cbf2d)

![[132014859] TIVAR® SuperPlus UHMW-PE Grey Plate, Size:15x1010x2020mm, Origin: MCAM/Germany (To Order Size, 15x1010x2020mm)](/web/image/product.product/14949/image_1920/%5B132014859%5D%20TIVAR%C2%AE%20SuperPlus%20UHMW-PE%20Grey%20Plate%2C%20Size:15x1010x2020mm%2C%20Origin:%20MCAM-Germany%20%28To%20Order%20Size%2C%2015x1010x2020mm%29?unique=01d1f8c)

![[132014874] TIVAR® TECH UHMW-PE Dark Grey Sheet, Size:3x1000x2000mm, Origin: MCAM/Germany (To Order Size, 3x1000x2000mm)](/web/image/product.product/14964/image_1920/%5B132014874%5D%20TIVAR%C2%AE%20TECH%20UHMW-PE%20Dark%20Grey%20Sheet%2C%20Size:3x1000x2000mm%2C%20Origin:%20MCAM-Germany%20%28To%20Order%20Size%2C%203x1000x2000mm%29?unique=ea29da4)

![[132014597] TIVAR® VMX UHMW-PE FG Plate, Size: 12x1220x3050mm, Origin: MCAM/USA (Sheet, Standard Size, 12x1220x3050mm)](/web/image/product.product/14261/image_1920/%5B132014597%5D%20TIVAR%C2%AE%20VMX%20UHMW-PE%20FG%20Plate%2C%20Size:%2012x1220x3050mm%2C%20Origin:%20MCAM-USA%20%28Sheet%2C%20Standard%20Size%2C%2012x1220x3050mm%29?unique=fa7bf7a)